Introduction

The digitization project of a two-thousand-year-old terracotta jar is a concrete example of how modern technologies can support the conservation and study of cultural heritage. The jar, discovered around 2005 in Mongolia, was subjected to a three-step process: digital imaging by laser scanners, photogrammetry and 3D printing. Each stage produced accurate digital models which could then be compared with the original, to assess the potential and limitations of the different techniques.

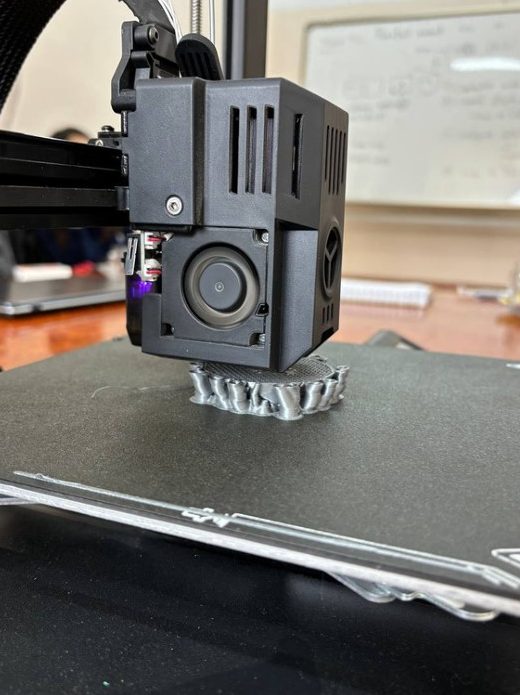

The project part I covered focuses on the third phase, namely 3D printing, a method by which the digital model takes physical form.

3D printing

For the reproduction of the jar was used an Ender-3 V3 KE 3D printer, a reliable and versatile machine that fits perfectly to projects of this type due to its technical characteristics:

- Printing technology: FDM (Fused Deposition Modeling)

- Print area: 220 x 220 x 250 mm

- Nozzle size: 0.4 mm (standard), with adaptation for smaller or larger nozzles

- Supported materials: PLA (Polylactic Acid), TPU, ABS

- Accuracy: 0.1 mm

- Layer resolution: 0.1 – 0.35 mm

- Print speed: up to 180 mm/s

- Extrusion temperature: 190-260°C

- Heated floor temperature: up to 100°C

- Software used: Creality Slicer (also compatible with open-source software such as Cura and PrusaSlicer)

- Connectivity: USB and SD card

The printing material used is Polylactic Acid (PLA), a bioplastic derived from renewable resources such as corn starch. This material was chosen because it is easy to use, as it is stable during printing and does not require high temperatures, also it is a biodegradable material, therefore eco-sustainable, and then allows you to obtain replicas with good definition, therefore ideal for objects of archaeological interest.

Steps for modelling

The main steps followed for the return of the model are:

- Preparation of the 3D model: the OBJ file of the digital model is imported into the slicing software (Creality Slicer), where it is scaled and placed in the virtual print area based on the size and capacity of the printer.

- Setting the print parameters:

- Layer thickness that defines the resolution of the print (e.g. 0.2 mm to balance quality and speed).

- Filling (infill), that is the percentage of internal density of the model (e.g. 20% to save material without losing strength).

- Support, that is an additional structure to support suspended parts or overhangs.

- Printing speed, which varies depending on the complexity of the model and the material used.

- Temperature, adjusted according to the chosen filament (in case of PLA: 200-210°C).

- G-code generation: Once the parameters are set, the software generates a G-code file, which contains all the instructions needed for the printer: nozzle position, temperatures, speed and print paths.

- Starting printing: the G-code file is loaded to the printer via SD card or USB connection. The printer heats up the nozzle and the printing table, then starts the process of depositing the filament layer by layer.

- Monitoring and post-production: During printing, it is important to monitor the process to avoid errors such as model detachment or adhesion problems. At the end, the model is removed from the floor and, if necessary, cleaned from the support structures.

The final model has shown a remarkable geometric accuracy, although it has some material limitations compared to the original terracotta. However, 3D reproduction has made it possible to create a physical copy which is accessible and usable for study, exhibition and conservation purposes.

Conclusion

Digitization and 3D printing are key tools for the preservation and enhancement of existing cultural heritage. This project demonstrates how new technologies can be successfully applied to archaeology, allowing not only to preserve ancient finds but also to make them more accessible to the public and scholars. In the future, the use of advanced materials and increasingly precise printing techniques will further improve results, opening new prospects for the protection and enjoyment of cultural heritage.

Leave a Reply